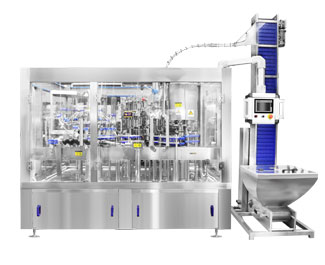

There are four main types of beer filling equipment: counter-pressure fillers, gravity fillers, isobaric fillers, and piston fillers. Each type possesses distinctive features and advantages, catering to specific brewery needs and production requirements.

Counter Pressure Fillers: Widely adopted in the brewing industry, counter pressure fillers employ CO2 pressurization to efficiently fill both bottles and cans with carbonated beer. Their versatility makes them a popular choice for various packaging formats.

Gravity Fillers: Operated by the force of gravity, these fillers may have a slower pace, but they prove highly effective, especially when filling non-carbonated beer. Their simplicity and reliability make them suitable for specific brewery requirements.

Isobaric Fillers: Adding an extra layer of precision, isobaric fillers utilize a vacuum alongside CO2 pressure to ensure the even distribution of carbonated beer in both bottles and cans. This technology contributes to consistent product quality.

Piston Fillers: While operating at a slightly slower speed, piston fillers shine in filling thicker liquids such as stouts and porters. Their piston mechanism accommodates a range of beer viscosities, providing versatility in the brewing process.